There’s a pressing issue in the United States—the shortage of skilled manufacturing workers. A study by Deloitte and The Manufacturing Institute in 2021 found that we’re looking at a potential gap of 2.1 million unfilled jobs by 2030. This could cost the industry a whopping $1 trillion. The study surveyed manufacturing leaders in the US and revealed that 83% of them are highly concerned about attracting and keeping workers.

With this in mind, it’s critical to understand the motivation of the employees you currently have. According to the same study, among employees under 25, 69% cited training opportunities, and 65% highlighted career advancement prospects as key reasons for their decision to stay with their current employer. Effective training for manufacturing programs is a must in the current landscape.

If you’re unsure what training is needed for manufacturing or how to implement a program, follow along as we lay out exactly what you’ll need during this critical time in your industry.

What is training for manufacturing?

Training for manufacturing is a specialized form of employee education designed to provide staff with the knowledge and skills to perform their roles safely and effectively.

Traditional classroom instruction and hands-on learning are parts of the training process, but immersive on-the-job training experiences work best. This can involve practices like job shadowing and informal coaching, where employees learn by actively doing.

There are many advantages of investing in manufacturing training, leading to boosted productivity, enhanced safety standards, and a more effective workforce.

How does training in manufacturing differ from regular employee training?

Manufacturing training is specialized education tailored for managers and employees within manufacturing companies. Although it shares some similarities with regular employee training, there are distinct differences that set it apart. Let’s explore what these are:

1. Prioritizing safety

Manufacturing training places a heightened focus on safety. This emphasis is crucial because manufacturing employees frequently interact with intricate machinery and complex processes. Comprehensive training ensures the correct usage of equipment, machines, and tools to prevent accidents.

2. Specialized skill development

Manufacturing training is particularly tailored to impart specific job skills, often centering on technology. This specialization is essential in the manufacturing sector, where success is gauged by productivity and precision.

3. Learning on the job

While employee training includes traditional classroom instruction, manufacturing training leans heavily towards on-the-job learning. This approach frequently involves activities like job shadowing and informal coaching. Many manufacturing employees grasp concepts better through learning-by-doing.

4. Consideration of cost and time

Manufacturing training can be relatively more expensive and time-intensive than conventional employee training. The necessity of training on specialized equipment and processes is the cause of this discrepancy. However, the long-term benefits of manufacturing training, such as increased productivity and elevated safety standards, often far outweigh the initial costs.

Manufacturing training distinctively focuses on safety and the acquisition of job-specific skills. It actively encourages on-the-job learning and may require greater financial and time investments, ultimately contributing to enhanced productivity and safety standards.

How do you create a training program for manufacturing?

Creating a successful training program for manufacturing employees is critical in providing them with the vital knowledge and skills required for a safe and efficient work environment. Here are some top practices for developing a thriving manufacturing training program:

Design your training program

Conduct a training needs analysis

Start by conducting a training needs analysis. By doing this, you’ll determine if the current training effectively achieves its intended goal. The first two questions to ask are:

- What’s the goal?

- Is it being accomplished?

If you’ve figured out that the goal isn’t being reached, you’ll need to determine who needs the training. Not all roles need the same training, so get clear on who you are targeting.

Set clear training goals

Establish transparent training goals, key performance indicators (KPIs), and objectives before training begins. This will help determine if the training was effective. Questions you’ll need to answer are:

- What’s the training objective?

- What’s the goal? You’ll circle back to this question throughout the training process.

- What KPIs are you using to measure progress?

- How are you recording and tracking progress?

Once you have clear answers to these questions, you can move on to the next steps.

Deliver your training program

Provide diverse training delivery

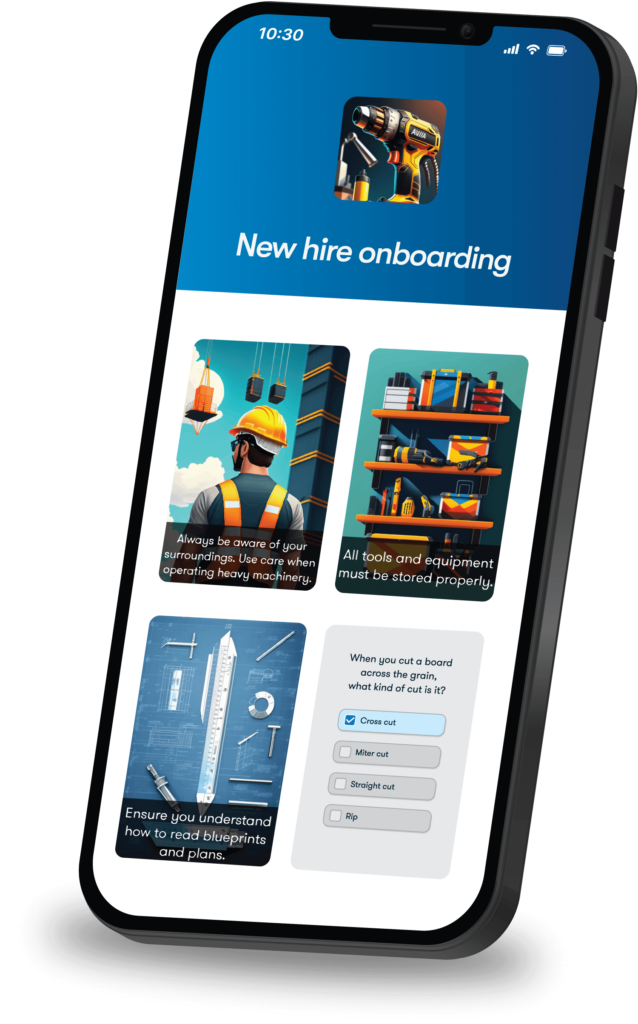

Opt for a blended learning approach, combining elements of classroom instruction, on-the-job learning, and e-learning through a mobile training platform. This flexibility allows you to reach a diverse set of learners. It’s common to find that one delivery method may work best for a certain training need, and another is more effective for something else.

Use qualified trainers

Identify qualified trainers with the necessary knowledge and experience to deliver effective training. Trainers can come from various roles, such as design and manufacturing engineers, manufacturing supervisors, and skilled production workers.

Maximize retention

To maximize learning retention, it’s important to consider how your staff learns and retains new information. The Ebbinghaus forgetting curve, a concept developed by psychologist Hermann Ebbinghaus, illustrates how information is rapidly forgotten over time if not reinforced. To combat this, one effective strategy is to incorporate microlearning into your training programs.

Microlearning involves breaking down content into bite-sized, easily digestible chunks. By delivering information in short, focused bursts, learners can absorb and retain knowledge more effectively. Microlearning is flexible and can be conveniently integrated into busy schedules.

Tap into the power of on-the-job-training

Manufacturer training programs hit the jackpot with on-the-job training. Why? Here’s the secret: it aligns perfectly with the 70-20-10 model. This model shows that 70% of learning occurs during real work experiences. That’s where employees get hands-on practice, applying their skills to day-to-day tasks. This learning helps individuals gain valuable insights and problem-solving abilities.

On-the-job training allows employees to acquire new skills while actively contributing to their work, enhancing job performance and competence. A dynamic learning environment is encouraged that goes beyond traditional classroom education. Practical, job-specific knowledge makes it a cornerstone for effective employee development.

Post training evaluation

Assessments for training effectiveness

Assessments evaluate the effectiveness of training for manufacturers. These essential tools determine how much employees have absorbed and understood the content. Regular assessments, such as quizzes, practical exercises, and formal or informal evaluations, provide insights into what has been learned and retained. These assessments validate the training process and help identify areas where continued training is needed.

Post-training observations

Post-training observations are direct observations of employees while they apply the training they’ve received in real work scenarios. This hands-on approach allows supervisors and trainers to determine how well the training translates to the work environment. Observations offer the opportunity to provide immediate feedback and on-the-spot corrections to ensure the employee can apply what they learned effectively.

Key performance indicators

Key performance indicators, or KPIs, provide proof of successful training. KPIs can include production efficiency, quality control, or safety records. By tracking KPIs before and after training, you can assess the tangible effects of the training program. For instance, increased production rates, decreased error rates, or enhanced safety standards can all be indicators of successful training. This data-driven approach helps make informed decisions regarding the training’s effectiveness.

Documenting employee training is part of a well-structured manufacturing training program that evaluates training effectiveness. Documentation ensures that employees have received the necessary training and is a record for your organization. Maintaining detailed records creates a comprehensive reference point for training outcomes.

Commit to ongoing evaluation for improvement

Training surveys

Training surveys are a must for any training program. Gathering feedback directly from employees on the training content, delivery methods, and overall experience provides invaluable insights. You’ll quickly pinpoint areas that may need improvement. Questions in these surveys can revolve around the training’s clarity, relevance, and how well it prepared them for their roles. You can use this guide of 30 training survey questions to create your own effective survey.

Feedback loops

Feedback loops should be established with employees, trainers, and supervisors. Open communication is encouraged for employees to express their concerns and suggestions about the training program. Regular feedback sessions provide valuable insights and a collaborative atmosphere.

Regularly evaluate the training program to ensure it aligns with the evolving needs of employees and the company. This continuous evaluation process helps identify areas for enhancement and facilitates necessary adjustments to the program.

Crafting a winning training program for manufacturing employees is a complex task. It’s about nurturing a culture of constant learning and growth. Following best practices while remaining adaptable equips your workforce with the skills and knowledge for success.

Make training accessible anywhere with a powerful mobile learning app

FAQs

What training is needed for manufacturing?

Much of the focus of training for manufacturing is on job safety. Some training areas include:

- Compliance and safety

- Quality control

- Industry-specific technical skills and regulations

- Machine operation

- Site management

- Toolbox talks

What are the 4 types of training for manufacturers?

There are several different types of training for manufacturers. Here are four of the top types of training:

- Compliance and safety training

- Lean manufacturing training

- Quality control training

- Industry-specific technical skills training

What is a manufacturing training program?

A manufacturing training program is a type of employee training designed to give staff the necessary knowledge and skills to do their jobs safely and effectively. The main goals of this program are to help employees:

- Work safely

- Increase knowledge

- Improve company outcomes work

There are different ways to teach this, like regular classroom lessons, learning on the job, and online learning.

What is the importance of training in manufacturing?

The significance of training in manufacturing cannot be understated. It is pivotal in driving increased productivity, improving product quality, enhancing workplace safety, keeping up with technological advancements, improving employee satisfaction and retention, and optimizing operational cost-effectiveness.

Comprehensive training programs serve as a cornerstone for manufacturing companies, ensuring their workforce possesses the expertise and proficiency to execute their responsibilities competently and securely.

Which course is best for manufacturing?

The best course for manufacturing will depend on the unique needs of your business and staff. Typically, the focus on learning will be to improve safety and productivity. You can find some ideas for training courses here.

Training in the digital age

As the manufacturing industry faces the impending skills gap, attracting and retaining talent, particularly among the younger workforce, is a priority.

Having a high-quality training program is critical to organizational success. Following the manufacturing training plan we’ve laid out will help you succeed in creating lasting and impactful learning experiences.

While we know training for manufacturing relies heavily on on-the-job training, it must be paired with an easily accessible learning platform like TalentCards. When done right, your training program for manufacturing employees will serve you for years to come.

Key takeaways

- The US manufacturing industry has a severe skills shortage, with a potential 2.1 million job vacancies by 2030.

- Attracting and retaining skilled employees is a top concern for manufacturing leaders, with 83% identifying it as a top priority.

- Young employees, especially those under 25, are motivated to stay with employers who offer training opportunities and a path to career advancement, with 69% valuing training and 65% seeking career growth.

- A well-structured training program for manufacturing is crucial in the current industry landscape, featuring diverse delivery methods and a focus on job-specific skills and safety.

- Regularly assessing training effectiveness, implementing post-training observations, tracking key performance indicators, and maintaining comprehensive documentation are vital to successful manufacturing training programs.

Create training your manufacturing teams can access anywhere with TalentCards